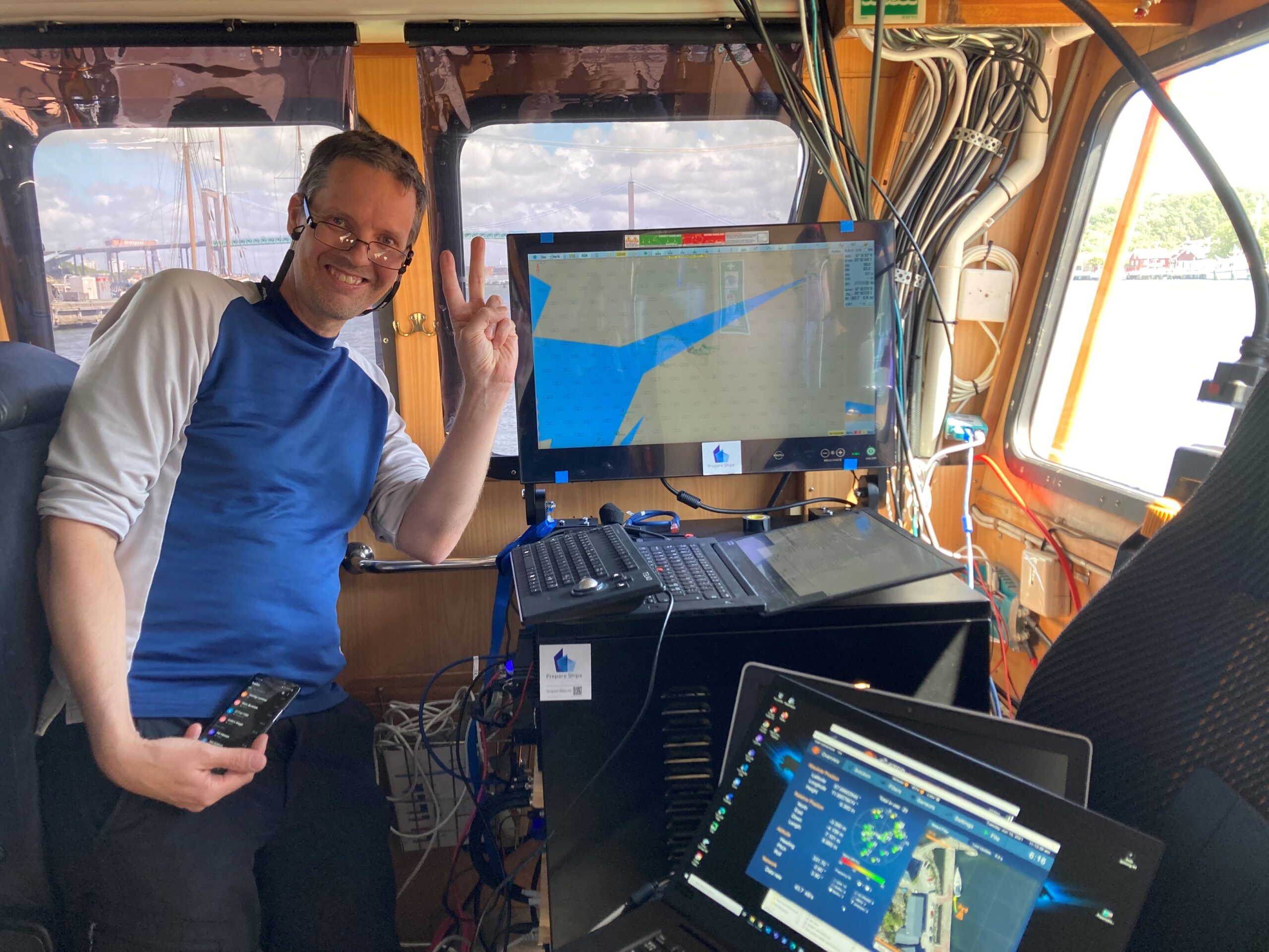

WP-leader Robert Rylander

Robert Rylander is a researcher at RISE Research Institutes of Sweden and the leader of Prepare Ships Work Package number 6 – Test and Demonstration. For RISE and Robert, the main objective for being part of Prepare Ships, is to make the shipping industry grow without compromising safety. For Robert personally, the ocean has always been a matter of the heart.

– Thanks to the Prepare Ships project I have the advantage to combine my two main interests: Informatics and Nautical science. We work with a concept that up to now has been used in aviation and automotive. This technology will now be implemented in the shipping industry for the first time to achieve higher safety at sea, and it is very exciting, says Robert.

Short about the WP06 objectives

The WP06 has the role of the focal point in the project. They test the systems developed by the other work packages, and after focus weeks with practical test, the system performance is evaluated and next steps are decided in tight collaboration with all project partners.

The test has so far been conducted in a lab environment where data streams are sent between the devices and different scenarios are tested to simulate the communication between boats and land. So far, the compatibility between the different systems seems to work out fine, when done in the simulations. But the ultimate test is the reality and that is what WP6 is all about.

– You can reach far with simulations, but in the end, you must test at real sites, under real conditions. These iterative tests are needed to validate the simulations and get input from both all project partners and the end users. Our focus will be to look for deviations that cannot be found in the simulation, says Robert.

Lessons learned

One important lesson during the project has been the insight of the crucial success factor is the domain knowledge. Engineering is important, but in the end, at sea, there is a challenging reality where the systems is to be implemented in and operate as expected. And the challenges are very different from other domains like the automotive where it is easier to reproduce and test situations.

– I think you can compare the idea of safety at sea as a spaceflight. In fact, you are not safe until you are ashore again. We have many partners who are from the maritime industry, but we have needed to train our partners, so they have a deeper insight into this specific maritime domain, says Robert.

Real site testing in the summer of, 2021

The first full scale integration test will be performed in June 2021 and the second in late August, where data is going to be transferred from boat to boat and from boat to land. The intention is also to make sure that the coast will get the information on the predicted routes to be able to plan the docking safely and avoid congestion.